The LCD used for printing on Elegoo Mars is RGB – there are three subpixels – red, green and blue. Since the backlight LED produces a quite narrow range of wavelengths (peaking around 405nm), only the blue filter passes the light. That means that 2/3 of the backlight power is wasted to the LCD. Also, it means that only 1/3 of the pixel is exposed and the rest is hardened only via exposure bleeding – the effect we, on one hand, want to eliminate, on the other hand, it is essential for properly working screen. After my modification, which removed the protective glass, you can see on my prints under a microscope the effect I mentioned – 1/3 of the voxel is nice and sharp, the remaining 2/3 are smudgy.

There were recently announced printers with monochromatic LCD. They feature low exposure times (around 2 seconds) with less power than Elegoo Mars. However, their LCDs have poor resolution.

So I was wondering – would it be possible to turn Elegoo Mars LCD to a monochromatic one?

The LCD stack up

First, I examined the LCD. I figured out that the two most outer layers are the polarizer. They are not glued, they hold similarly like to protective glass. Then there is a bottom plastic film with the pixel electrodes (I am sorry for not providing pictures, however, I was not able to take them from the microscope). Then there is a glass layer – on one side (the top side) it is covered by ITO – a conductive clear coating. On the bottom side, there is a layer of color filters. Between the glass and plastic film is a layer of liquid crystals, more specifically between the plastic film and the filters.

One important part – the ITO layer is connected to the plastic film via a conductive ink – see photo below.

The procedure

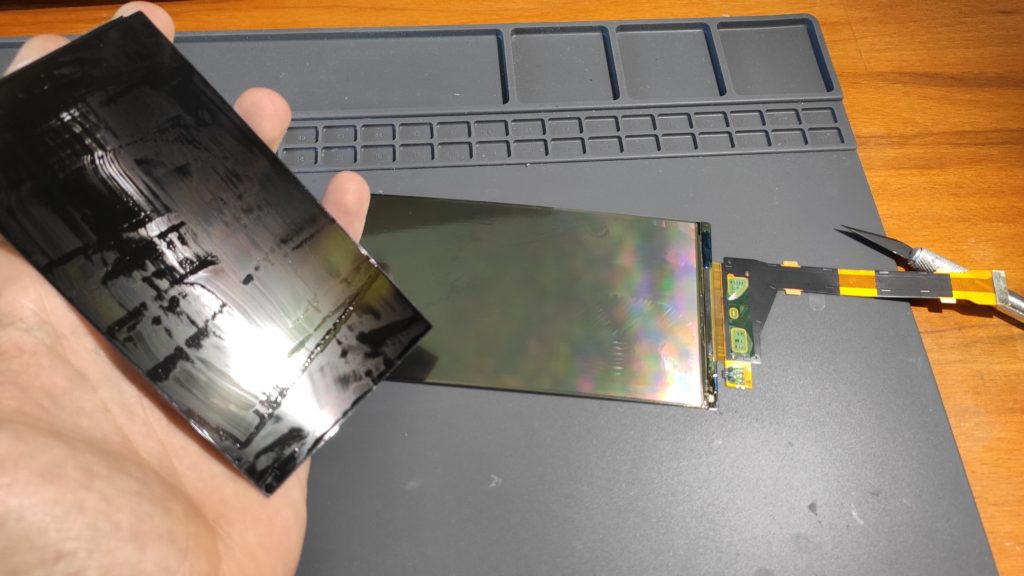

Having experiences with disassembling LCDs before, I know how to separate the glass from the plastic film. Just use a fresh Xacto knife and slide it between the layers, move along the perimeter and the layers separate:

You can nicely see the liquid crystal. I used a rubber spatula to save as many crystals as possible from the glass. Then, I started to scratching of the filters. It was pretty easy using a knife. I decided to leave the black border – it probably provides correct spacing between the layers – but I am not sure.

I started to scratch the filters off

Nearly there!

Finished!

You can see that the glass got much more transparent. Then I cleaned it properly and put the LCD back together. Unfortunately, I was not careful enough and I got some dust particles to the crystals. Therefore, I got polarizing patterns on the LCD:

I connected the LCD to mars and run an exposure test. To my surprise, the LCD was working – you can clearly see the test pattern:

So – it is possible to do! To fix the issue, I separated the layers again, cleaned them both with IPA using a paper towel, put liquid crystals I harvested from an old computer screen between them. I got LCD without dust particles, but with strange, colorful, patterns:

Unfortunately, the LCD stopped working. I have no idea why, just a few theories:

- there are different type of crystals and they are not compatible,

- by cleaning the LCD with IPA and paper towel I corrupted the pixel electrodes,

- or I destroyed micro scratches in the surface – see the video by Applied Science about the scratches

- or something else.

Also, I don’t know what caused the colorful effects after using the crystals from a big LCD. Do you have any ideas? Please, leave a comment.

To do more experiments, I am looking for screen donors – I look for people willing to send me their LCDs with dead pixels. Doing these experiments on brand new displays seems to be wasteful to me. So if you have such a display and you live in Europe, please contact me!

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

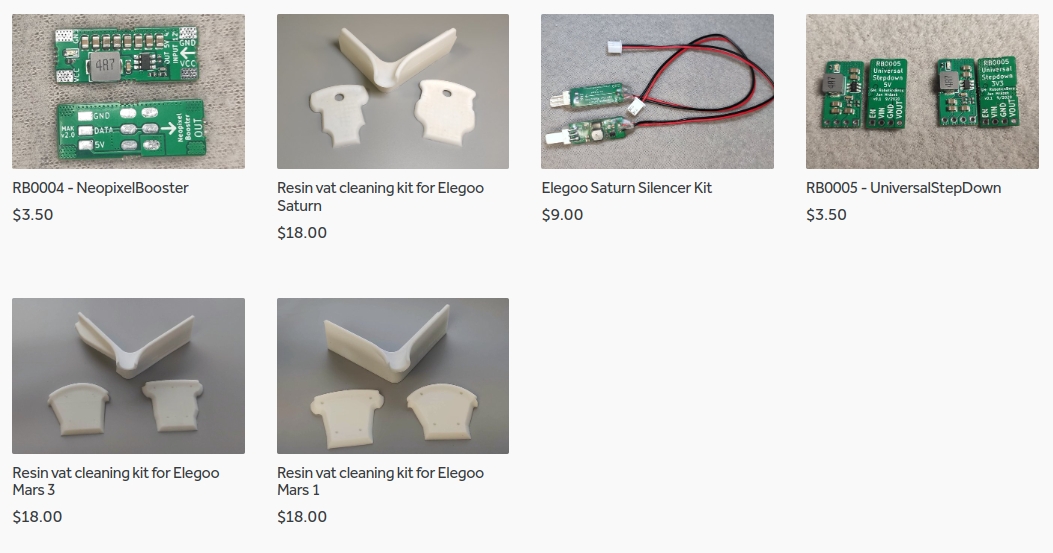

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

So the colours can be from a difference on the polarizer type used by the donnor screen or a bigger difference on the spacing beads the donnor screen uses (microspheres that keep the two halves separated)

For future reference here is a curated list of videos on how LCDs work

http://bit.ly/HOW-LCDS-WORK

Very cool, but from what I’ve seen and read of the LCD manufacturing process, it’s pretty much impossible to replicate to the precision needed for this to really work.

That black border bit is a sealant. It’s layered on thicker than the intended gap. Then, while in a vacuum, the 2 halves are brought together ( with the liquid crystals between them. ) The vacuum is needed so the gap will not have any air bubbles. ( I’m sure the exact specifics of this part will vary from company to company though. ) Then the panel is squeezed under a heated plate down to the proper thickness compressing the sealant. This part requires precise temperature and pressure control. Too much pressure and the spacing beads get crushed. Too little pressure and it doesn’t seal and the gap is too thick. Much the same with temperature. For simpler LCDs this isn’t an issue, but when you’re dealing with these high resolution, small size, advanced panels, I’m not sure it can be done by hand at all.

The color pattern is “Thin Film interference”, the same thing that causes oil sheen or rainbow colors in a soap bubble. If you go back and look at your working one, you can see it there as well around the edges of bad spots. Because of this, I think it’s variances in the thickness of the liquid.

As for why it broke, my money is on the IPA with the paper towel wipe being close second.

I plan to try emailing a display manufacturer about the feasability of taking an existing panel and just skipping the color filter stages. This could actually allow them to make special 3d printing panels that allow a lot more light AND probably cost a fair bit less. It takes quite a few steps to apply the color filters after all.

I doubt it is this easy, otherwise they would do it already.

Maybe if they just made all 3 filters blue instead of skipping the step.

We can hope that the market is now big enough to warrant a special screen only for printing. But, it’s likely to be much more expensive since it won’t have the volume that the standard screens would.

Yea, things are rarely as simple as they seem they should be. My guess would be the gap left by not doing the colors could be too great. If that were the case, then your idea of rerunning blue would be a great alternative, thanks!

Yes, I too think we’re in that middle step. There’s enough market to start looking at ways to make screens better for 3d printing, but going full in on it is likely to only be viable for high end printers…which naturally don’t have the volume yet. This is why I’m crossing my fingers and hoping something simple like just pulling some screens out from a few steps is viable.

If this technology continues to grow though, I think there’s lots of other areas a dedicated screen could try to improve. For example, we don’t need super thin overall, just the top to be thin. So, give the bottom a nice thick sturdy piece. Maybe try to thin the top even more. Harden the top surface. Make large bezels for mounting. Improve UV resistance. I gotta stop…I’m drooling over here thinking about the possibilities:)

Hi, I have a few ideas.

What about using the monochrome display from an old till? Some of these can be quite large.

Also maybe find a very old laptop with B/W LCD and use this?

Have a fair few old style CCFL backlit laptop screens here including some smaller units.

You are more interested in smaller pixels than large build area (the screens we are talking about have pixels around 47um, standard screens you are talking about have around 300um). Also, I am not interested in building a new printer from scratch – there will be more high-resolution monochrome screens coming in the next year. I am interested in upgrading the old printers – there more than 100k of them out there using the Sharp LCD.

I don’t really know anything about it yet, but a user on the subreddit just posted a link to this:

https://mailchi.mp/a6920f4fb061/resin3_upgrade

Supposedly they are making a 2k monochrome lcd that will be drop in for us. Fingers crossed!

I’ve seen it and subscribed. However, I am not sure how he wants to create a 4k replacement – the motherboard of most of the printers is not capable of driving such LCD (just given the size of the framebuffer on the board).

I mentioned the same thing:) Apparently they are also going to supply a new board with it.

Without some method to collimate the light though, I don’t see a point to the 4k at 5.5″. The light bleed is already limiting the 2k screens, and removing the glass protector and using 0.05mm FEP isn’t really viable for most people. Now, a 4k at 8″ could be fantastic.

Well, then it won’t be a simple, cheap drop-in replacement any more.

Regarding 4k at 5.5″ – I think removing the glass is pretty simple and practically anyone who can replace the screen can also remove the glass. Also, if you get a monochrome replacement, you can already manufacture it without a protective glass and a suitable mounting attachment.

Yea, though if we could make use of the 4k improvement, I would have been fine with the extra work, as I’m sure you would have.

Yes, I know you can get the LCDs without the glass cover ( That’s exactly how I ordered mine ), but actually printing like that regularly, especially for the vast majority of users is just not viable. NTM I was saying that’s just to get the full use of a 2k screen, so a 4k would likely still be overkill then. The 0.047mm pitch seems to be the ideal unless we can completely eliminate the various sources of light bleed. That same pixel pitch can be maintained at 8.15 inches with a 4k screen. That would be a nice size increase without any loss in detail like the 10+ inch machines we are seeing now. ( Of course it would essentially mean a whole new printer. I’m just saying that would be a nice actual upgrade over the Mars and such. )

Question, how long has the screen on your previous mod lasted without the protective glass? How many prints, or layers?

I have prepared to do the same mod with my backup screen, but I’m concerned that it will get damaged too quickly.

What are your experiences?

I have printed 3+ kilograms of resin before I had to replace the LCD. Even after 3 kilograms, it died from my own stupidity when I started a print with several fractions of previous print left on the build plate. It created two small black spots.

I recently saw on ctb web shop 6 ” mono screen with chitu board and led array for about 200 usd with some CNC I could cut the main alu plate on Mars /photon and will have 6″ mono with chitu L board

Yes, it is available. However, the display is only compatible with the newer board in Mars. If you have a board that expects an angled LCD connector, you are out of luck and you have to also change the driver board. See the Photonsters page on Facebook and Github for more details.

Have you ever thought of bleaching the color pixels? With bleach or ozone?

That probably won’t work for several reasons:

– you still need to disassemble the LCD to reach the filters,

– if you are thinking about dissolving the filters without disassembling, I guess it would also dissolve the liquid crystals,

– I think the color couldn’t be bleached (just like you can’t bleach acrylic)

Nice experiment. Leaving resin broke the first lcd? how?