Resin printing is wonderful. I love it – it’s fast and detailed compared to FDM printing. Also, the materials are getting better and better. However, compared to FDM printing is a really messy process. The resin frequently drops where you don’t want it to, and you have to wash the models in an IPA bath.

And here comes the problem – how should you safely dispose of a dirty IPA bath? The resin before it is cured is toxic, especially to aquatic life. The best way is to probably bring the bath to a facility for hazardous waste disposal. Nevertheless, the idea of recycling IPA is appealing so you see a lot of people on YouTube and Facebook trying to clean it and recycle it.

Here I bring my 2 cents on the topic. Note that what I present here is more of an idea or a proof-of-concept rather than a complete solution. Also, I am no chemist, so I cannot guarantee that the presented procedure actually yields safe waste. If you have some insight or ideas, please, let me know in the comments!

The roll after the second experiment. The drum was spinngin to fast (40 RPM) so this the the result wasn't a hard material, but a hard jelly. When I let it sit ouside for 2 days, some of the IPA got away, but it cracked

Double bath approach

First, let me start with this: If you don’t use a double bath (dirty/clean) for cleaning, start now! Double bath cleaning makes your cleaning process more efficient (I can clean 10–20× more printed resin using a double bath than with a single bath approach). If you want to learn details, see my post on this topic.

In short, you should have a dirty bath where you do your first round of washing. This will remove most of the resin and should you leave with a model covered in a thin film of the dirty bath. Then you clean it in a clean bath. The principle is that you almost don’t care how much dirty your dirty bath is, the only goal is to remove the excessive resin. Then your clean bath lasts much longer.

What have people already tried?

Back to the topic. Let’s start with a brief recapitulation of what I found people on the internet are doing in order to dispose of or recycle the IPA bath.

Some people simply put dirty IPA in a container and let it evaporate in the sun. Once the IPA evaporates, the resin cures and solidifies. Most manufacturers claim that cured resin is a safe waste. Most people report good experience with this. I tried it on a small volume and I run into two issues: first, my dirty bath was so dirty, that it ultimately blocked light within half a millimeter (see explanation) so I was left with a solid resin cylinder with half-millimeter walls that was full of dirty IPA. The second thing where I have doubts is whether is actually good for the environment to let IPA evaporate in the air.

Another approach is to let the resin sit in a dark container for a long time so the dirty part settles. In my experience, what settles are only the pigments and fillers, but most of the components of the resin are left in the IPA. When you put paper in a bath cleaned in such a way and expose it to light, it will actually harden. So, this approach didn’t work for me. You are still left with a dirty bath that will only make your prints sticky.

Another approach is to let the resin sit in the sun. The resin forms a white gel. Some people claim that after a long time IPA separates from the gel, but I wasn’t able to verify it. For me, it never separated.

There was also an approach of using aluminum sulfate to clean the resin. Aluminum sulfate is often used as a coagulation agent that’s added to water to clean it. I haven’t tried this, so I cannot make any claims about it.

The last approach is distillation. I haven’t tried this as it’s relatively dangerous when done wrong, has high input costs, high running costs (come on, 1 L of IPA costs 2€!) and also, I am not sure if the boiling point of IPA is below the boiling point of all the volatile parts of the resin. If somebody knows, please, let us know in the comments.

What seems to work as a disposal method is soaking paper towels in the bath and curing the towels. However, this is extremely messy and laborious. But the resin solidifies nicely, so it should be safe to dispose of.

Another spin on the resin disposal

The solidified resin should be safe to dispose of. However, how to cure the resin in the solution of IPA? If we shine through it, it will not cure though due to the pigment in the dissolved resin blocking the light. And we also risk that we only form a white gel from which we won’t be able to extract the resin.

I came up with the following device – it is a slowly rotating paper roll forming drum, that is by 1/3 submerged in the dirty IPA. On top of the devices are high-power UV LEDs. The whole device is closed in an air-tight box with the IPA. As the paper tube slowly rotates, a thin layer of the dirty IPA forms on it. It should have enough time for the IPA to evaporate. Once it reaches the top, the UV LEDs cure it. In this way, we simulate what a printer does – curing thin layer by thin layer. After a while, we should get all the reactive components from the bath onto the roll in a cured form.

I made a quick & dirty prototype; to verify the hypothesis. The prototype was printed on an FDM printer with a 0.8mm nozzle. This is why the print is a little rough. It is powered by a small DC motor. The LEDs on the top have 10W in total. Everything is wired “as is” and it is powered by a lab bench power supply.

First, I tried the design with only 1 LED attached. To my surprise, it ended up well. After a minute, you could see that there is a layer of resin forming under the LED. I let the device run for about 25 minutes. The dirty bath got notably cleaner (though, not completely clear) and the paper tube under the LED was covered in a thick layer of hard resin. I washed the roll and cut it in half. It seemed that the device worked as expected. The resin on the tube was darker than the dirty bath, and it was rock solid throughout the whole depth. When you look closely, you can see the individual layers. You can also see that the layers get lighter and lighter towards the outside – as we extracted the dirtiest part of the bath.

The cross section of the first experiment. The material is hard – seems like mostly resin.

Detail of the crosssection.

Given this success, I designed a second prototype with an array of LEDs and some small improvements. This time I switched to another motor, that I thought would be more suitable. The second experiment turned out as a partial success: the LED arrangement was great but the motor wasn’t suitable. It wasn’t able to spin slow enough, so instead of nice hard cured resin I got hard (but dry) jelly – probably a lot of IPA got captured in the resin structure. Also, this time I used a magnetic stir bar and magnetic stir board. This has shown as a good idea as it cleaned the resin more evenly.

The roll after the second experiment. The drum was spinngin to fast (40 RPM) so this the the result wasn't a hard material, but a hard jelly. When I let it sit ouside for 2 days, some of the IPA got away, but it cracked

You can even see on the cross-section that the material has different structure compared to the first experiment.

What I learned from these experiments:

- I need to switch to another motor; either with a high gear ratio or a stepper. It seems that the optimal rotation speed is about 1 turn in 1–3 minutes. If you go quicker, a lot of IPA gets trapped in the cured resin and you get a hard rubber, not hard resin. There is the time needed for the IPA to spontaneously evaporate so only mostly resin stays on the drum.

- The LED power seems more than sufficient; I actually used only 2.5 W of the original 10W of power. However, a more even pattern is needed. On the other hand, when I rotate very slowly, the pattern might not matter that much.

- The hubs for the paper roll need to be coated in mold release otherwise they stick really hard.

- The hub needs openings so that when IPA gets inside the roll, you can pour it out.

- Overall, the idea seems to be working – it just needs further tuning so it is actually convenient.

My idea is that it should be something you put inside an air-tight and light-tight container and let it run for 1-2 days. During this time, it should cure all the resin components on a disposable roll that you can then trash.

Do you have any ideas on improving this method? Do you see some flaws in it? Let me know in the comments!

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

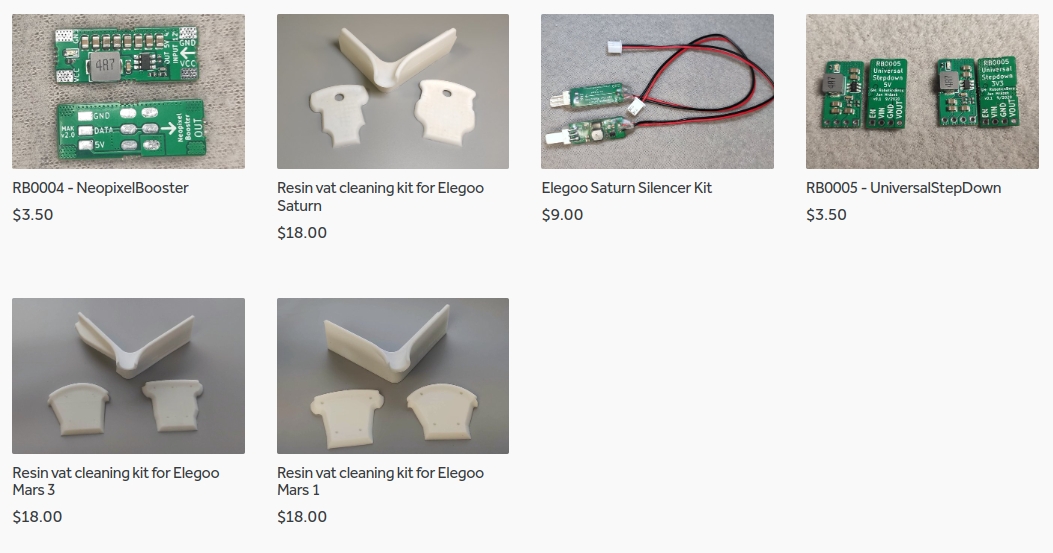

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

Related Posts

- Multi-planar Slicing for 3D Printers – For Both FDM and Resin

- Open letter to the 3D printing community: Let’s be better in 2023! What should we do?

- Continuous Printing On LCD Resin Printer: No More Wasted Time On Peeling? Is it possible?

- About the Successful Quest For Perfect MSLA Printer UV Backlight

This looks really intriguing, great research into one of the ugliest part of the hobby!

One thing I’d love to see factored into a v2 would be stronger isolation of the electrical components from the IPA. It may be overcautious, but creating a fuel/air mixture, in a sealed tub of flammable liquid, with electrical components that are not rated for that environment makes me nervous. If that could be overcome at a design level I think it would be an improvement, even if weaker isolation is *unlikely* to cause issues. Perhaps magnetic coupling through the body of the tub could allow for electrically isolated rotation of the wick tube. Air movement would obviously be the most difficult thing to fully isolate…

Regardless, great stuff!

Thanks for the response! This what indeed, a hacky prototype just to find out if it is even remotely possible. And the device was under constant supervision. I agree with you that it would suitable to put the motor out of the IPA container (the LEDs shouldn’t be a problem and since they have to illuminate only the drum and be close, they probably have to be inside the contianer.

Wow, such a great idea!

As usual, I am astounded at the scientific approach you have to this blog.

I’ll have to try and design something similar myself 🙂

One reaaaally tiny detail: it’s (usually) not pigments that prevent UV from penetrating resin. If you look at the autodesk resin formula you shared earlier, you’ll notice there’s UV blockers in the mix. They have to be there, otherwise printing any type of overhangs would be impossible.

Or at least this is how I understand the process.

Back to the topic: how about covering the hub in silicone instead of spraying with mold release? I would also be tempted to try something durable instead of the paper towel roll. Don’t know what though 🙂

My experience with leaving the resin under the sun form a thick gel is to go out and shake the heck out of the transparent pfte juice bottle and break the gel.., then the separation between the ipa and the sun cured resin precipitating to the bottom gets way better. Then i pump the IPA with a peristaltic pump rather than a siphon… then afterwards I think distilling the cleaner IPA is really the way to get back something that’s as good as the original stuff. But i’d be interested to know what you are able to have cooking with your stuff

I have also experiments featuring FDM or resin printed replacement. At the moment, I was considering the role as a consumable.

I like your comment about silicone coating, but perhaps it could be taken a step further and instead of using the toilet paper roll, have a silicon tube that can be reused? If it was flexible enough you could just deform it to pull it from the center of the cured resin.

This has got me thinking I need to give this a try myself. How is the motor mounted? I was also considering using a continuous rotation servo so that the speed could be easily controlled.

Would you be willing to share your design files?

Thanks for posting this!

Super nápad!

Určite to budem musieť skúsiť.

btw. prosím ťa kde v česku kupuješ isopropylalkohol 1L za 2€ ?

Ja používam technický líh 1L – 80 Kč (DM drogerie) pretože som myslel že je levnejší.

In Switzerland IPA cost about 15 Euro per liter, so re-use it is a MUST! I use the destilation method and really love it. Very clean ISO afterwards and less messy than any other method. Downside is a loss of about 15%.

How is the status of a V2 design? And can you share the details of this design? I would like to build this and try myself. Can you share the STL files to print and details about the motor, LEDs, and other electronic connections?

Really interesting approach to cleaning up the contaminated IPA.

I think others have suggested this, but adding a cold plate for the evaporated IPA to condense on would help recover more of the IPA, instead of letting it stay in vapor form. So maybe set the roller on one end of the box and the chiller at the other end. perhaps fan blades to the roller assembly to also add air flow towards the cold plate.

Another though is… could the curing of the resin be extracted in a useful form? Ie, instead of just tossing out a tube of uneven build up… have it be usable as something like… storage container? Planter?

I also came here to say a condensation surface might be a useful addition to improve the evaporation of IPA from the resin on the roller. I realise no-one wants to pay for energy transfer but a peltier cooler might be a good start for testing. You could integrate the thermal interface with the lid of the box, so that there’s a cold side heat exchanger inside the container (e.g. aluminium cooling fins) and a “hot” side outside the lid to transfer heat away from the internal volume of IPA vapour. Insulating the top section of the enclosure might be useful but you want the liquid IPA in the bottom to reheat for the next cycle round the drum, so probably leave the bottom thermally connected to the environment (ie don’t insulate it). If you can “dry” the air of IPA vapour just before it is blown onto the wet drum surface, that should make the drying process more efficient.

The continuous cycle of the drum roller is good but I wonder if either dripping / spraying the agitated IPA-resin mix onto a silicone sheet , perhaps at an angle, or periodically submerging and lifting a surface before blowing it dry might help.

Just found your blog and having bought the Saturn 2 as my first resin printer, I’m very grateful for your work.

If the leds are in the same enclosure as the IPA, doesn’t some scattered UV light get into the IPA and cure some resin while it’s not on the tube?

Maybe a spiral built into the inside of the drum so that liquids inside it are constantly pulled to the end of the drum to a drain. Similar to the inside of a concrete truck.

If you seal the entire operation, how much vapor pressure is there? I thought about mildly heating the drum and putting a cool spot on the side for condensation, but I think that makes it more complicated for little benefit. But I’m curious if adding a pressure equalization diaphragm would help reduce IPA loss from vapor escaping because of pressurization.

Hey,

I am an engineer who works in AM, I am wondering if you are willing to provide electrical schematics or a BOM? This is a really good solution to providing longer life span of your IPA.

Hi, love the concept and experiment to prove it out!

My only concern is that with a refined version in a sealed container the air in the container will quickly become fully saturated with IPA and so the IPA will no longer evaporate off the roller as it slowly moves through the air. I suspect the prototype was helped a lot by the fact the air it was surrounded by had a very low concentration of IPA, meaning the liquid IPA on the roller could easily evaporate.

Definitely worth testing though, I wonder if the stickiness + viscosity of the resin compared to the IPA is also helping to separate the two once the a patch of the roller rotates out of the solution. If so, there may still be a chance it works similarly well in a sealed container, and maybe some ribs to bump up the surface area could help bump up the rate it can extract the resin at.

How is the status of a V2 design? And can you share the details of this design? I would like to build this and try myself. Can you share the STL files to print and details about the motor, LEDs, and other electronic connections?

This is the coolest build I’ve seen in a long time. Sell one and I’ll buy it.

Hey, thought this was great, and I had recently gotten a resin printer. I decided I would take a stab at doing this myself and here is and Imgur album of my first version!

https://imgur.com/a/8jRux5L

It uses a silicone beaker to that it can be pulled away and reused, uses magnetic coupling to keep electronics away from the liquid, and works with the lid closed!