A while ago, I presented my finding on why the prints do not stick to the build plate and why is there an elephant foot formed on resin printed models. Then I made a follow-up post where I presented a plugin for UVTools that automates the process. However, a few months passed, UVTools 3 was released, and the script stopped working. Fortunately, the functionality I presented was built into the UVTools. Since I frequently receive questions on how to use it, I decided to write this short “how to” guide.

Using suggestions to add rest times in UVTools 3

I assume that you have already UVTools downloaded. Adding rest times is hidden under the suggestions tab. The suggestions are a set of semi-automatic sanity checks of your file. When they detect unusual settings, they allow you to fix them. The usage is simple, follow the image guide:

Open UVTools

Load the file

See the loaded file

Open the suggestions tab

Open suggestion settings

Set the values. Don't be afraid to change them according to your printer

Set additional values.

Optionally, enable waiting after curing.

Apply all suggestions

Confitm.

Done!

The result.

Supported file formats

This method works well on CTBv4 format that is supported by most of the Chitu-powered printers on the market. It doesn’t, unfortunately, work on Anycubic devices as they don’t support per-layer settings. Also, note that if you use Lychee slicer, the default output format is CTBv2. Change it CTBv4 to use this method.

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

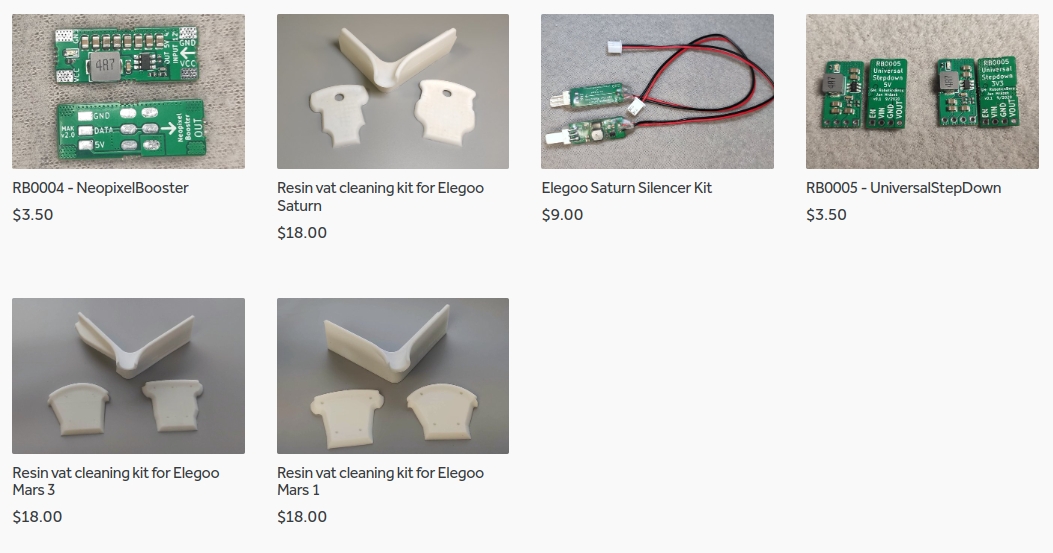

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

Related Posts

- Multi-planar Slicing for 3D Printers – For Both FDM and Resin

- Open letter to the 3D printing community: Let’s be better in 2023! What should we do?

- Continuous Printing On LCD Resin Printer: No More Wasted Time On Peeling? Is it possible?

- About the Successful Quest For Perfect MSLA Printer UV Backlight

hello! I really appreciate this blog series, however I got stuck trying to follow this foolproof series of instruction photos, using the latest uvtools.

Entering the same numbers (and a bunch of other numbers that should have triggered the action) no tickable box appeared to apply the wait-before-exposure thing, and so the ‘apply’ button was always greyed out too. I use a mono x, the anycubic slicer, and the segmented dragon model. Note that the blank base layer never appears, and also that this immediately appears in the ‘applied suggestions’ box with no evidence of having made any changes.

Any ideas? Is there a way to inspect logs etc for uvtools or this script?

You have to first select all suggestions that you want to apply. Then you can click the apply button.

Thanks, I couldn’t figure out why UVTools wouldn’t add the empty first layer on my sliced saturn files. It was ctbv2 from Lychee :/

Hi Honza,

could you please provide a bit more info regarding the formulae behind your settings?

I can’t seem to find a more detailed description of the features and don’t really understand the tooltips…

Thanks and BR

The idea is that the time needed to remove blooming and elephant foot depends on the machine, how close the build plate is to the bottom of the tank, and the model cross-section.

Therefore, what UVTools ask you to do is:

– decide how long you should wait when the build plate is completely full when it is near the bottom (the initial layers)

– decide how long you should wait when the build plate is completely full and when the build plate is far from the bottom

– decide if you want to introduce a minimal delay or put a hard limit on how long you want to wait.

The numbers are best “guessed” on experience. If you experience blooming, increase them. They can be precisely determined by measuring the force on the build plate, but this is not what a common user can do. The numbers I give are basically something that seems to be a decent compromise between quality and print speed. They are based on trial an error on over 100 prints.

Hello, can I ask how Elephant Complete Foot Removal is?

img : https://imgur.com/IyPj9uv

I am not sure if I understand. Do you ask how effective the method is? Then please, refer to the original blog post explaining the method:

– https://blog.honzamrazek.cz/2022/01/prints-not-sticking-to-the-build-plate-layer-separation-rough-surface-on-a-resin-printer-resin-viscosity-the-common-denominator/

– https://blog.honzamrazek.cz/2022/02/a-step-by-step-guide-for-the-perfect-bed-adhesion-and-removing-elephant-foot-on-a-resin-3d-printer/

Hi Jan, UVtools and your blogs have improved my prints immensely, but I have a different printer (Epax E10) and am thus diving down the rabbit hole of calibration tweaking.

Could you explain how the proportional wait time settings in the Suggestions – Wait time before/after cure menus are used?

The tooltip says “Sets the wait time according an (wait time – exposure time) ratio” but I’m not sure what that means. Where are the numbers for wait time and exposure time supposed to be coming from for the ratio calculation? Is the value we input supposed to be the ratio or is it a specific value from the waiting process?

Also an unrelated question, my prints sometimes have crescent shaped over-curing patterns repeating across a surface when printed diagonally on two axis. They’re blobs of partially cured resin and can easily be sanded away, but quite a nuisance on non-flat surfaces. Any idea what could be causing this? https://postimg.cc/gallery/RZ0vHC8

The bigger cross-section you have, the longer you should wait. UVTools allows you to specify a reference cross-section and a corresponding wait for this cross-section. UVTools will then calculate the rest time based on the previous layer cross-section. What I advise is to set the cross-section to the area of your build plate and set the corresponding wait time according to your machine (it should be in the range of 10-30 seconds based on the machine rigidity).

The pattern you see seems like a wrong pattern on display. It could be either a damaged LCD or a bug in the driver software. Try running the print without a build plate and vat and observe if the displayed image is correct.

Hi, I’m setting this up for the Saturn 2. I noticed you say to set the cross-section to the area of the build plate, but I noticed you set 10000 for the Saturn while the area should be almost 25000 (196×126). Are you suggesting we should set it to the width of the build plate (in your case, 126 mm)? Thank you!

Hi Jan,

I’ve been printing more and more on my build plate ever since your first elephant’s foot removal guide. Tell me, as a programmer and engineer like I am, do you print many enclosures or boxes for PCBs? I find such open boxes to be the toughest to print because of the suction cups that screw holes and magnet mounts make. They often cause the whole print to stick to the FEP.

Printing them off the build plate (on supports) works but the number of supports for a flat planar surface like a box makes cleanup very tiresome. So I’d like to know if I can print them on the build plate. Do you have any tips?

I often add a small (2mm) ventilation hole which I then glue in or leave it.

Hello Jan,

Thank you for this great guide!

Quick question, Chitubox has a “rest time after retract” enabled by default on the Elegoo Saturn 2 with a value of 0.500 sec.

Should I set this value to zero since UVtools is adding a “wait time before cure”?

I believe UVtools is overwriting this value to match its settings for “proportional wait time”

Could the “rest time after retract” setting in Chitubox cause any problems with UVtools?

Thanks!

UVTools just override all the settings. No problems with values left by Chitu whatsoever.

Hi,

in chitubox there is light-off delay and bottom light-off delay. We can calculate how much time we need for lifting and retracting based on defined parameters and then add pause time – separate for bottom – 40 seconds like you suggest or 1-2 seconds for normal layers. Would not it be the same? HOwever in this approach you cannot set rest time after cure. Would be good to have possibility to define all thre rest times separatelly for bottom and normal layers.

Regards,

Dobrosław

This procedure sets rest times and delays after cure just fine (that’s what this step is doing: https://blog.honzamrazek.cz/wp-content/uploads/2022/07/step8-1.png). It can even set it independently on whether the layer is a bottom one or not. It can also set the delays based on the actual cross-section size of the previous layers.

Why bother with “light-off” that (stupidly) includes movement when you can just set the actual time to wait?

Dear Jan,

thanks! As far as I understand I run this procedure with every file I want to print – by using UV tools & this procedure, I am modifing g-code after slicing in original software, and then upload modified file into the printer.

Hi Jan. I’ve just found your blog after following the link from Uncle Jesse’s Youtube video on your dummy print leveling technique, and I’m so glad I found it!

Quick question – in image 6/12 you say these are the settings you use for the Saturn and you say we should adjust them for our own printers. How would I adjust the settings for an Elegoo Mars 3 Pro?

Thank you for your help

Using a Saturn 2 and Lychee and tried following your guide, but settings looks nothing like what you show in this article in UVtools now so I’m at a bit of a loss how to apply the guide. I love how my brand new printer prints, but I can not print directly on the bed as I get a pretty severe elephants foot.

You have to use CTBv4. Lychee, by default, uses CTBv3, which doesn’t have any per-layer settings support. Also, with Saturn 2, I suggest using longer base times as it has much worse mechanical construction.

this is terrible advice as it will double to more than triple cycle time for basically no reason. theres far superior methods to get rid of elephants foot. and if your having adhesion issues your just plain doing something else wrong.

Hi Josh

Please inform us of these superior methods for elephants foot removal

Hi Josh! I am also interested in knowing about your better methods. I agree that this prolongs the printing time (though only by 20-30 %), but there is a lot of reason for it. Just read my original post that explains why this method is so effective: https://blog.honzamrazek.cz/2022/01/prints-not-sticking-to-the-build-plate-layer-separation-rough-surface-on-a-resin-printer-resin-viscosity-the-common-denominator/

Hi Jan,

Thank you for all the research you have done to make resin printing better for everybody. I was having A LOT of trouble with printing functional parts with large cross section, flat on the build plate. I was using Siraya Tech Blu and the Anycubic Photon Mono X 6K, heated room.. The bottom layers would come out WAY too thick, it was driving me crazy. I could hear the stepper motor skip steps as it would calibrate the z-axis before printing. Probably a combination of the difference between Z=0 and sensor home (due too mag plate) and really thick resin. So the resin couldn’t squeeze out between plate and screen, bending the screen and frame. Since Anycubic lacks ‘per layer adjustments’ I couldn’t really change much about wait times for initial layers. I ended up selling the Anycubic and buying an Elegoo Saturn S (cheap €200 open box deal), as it should work better in combination with UVTools. Now I’ve been reading a lot of your blog posts, and I feel like you present a lot of solutions to mitigate the problems I was encountering. I never understood the extremely long burn-in exposure times everybody recommends, but now it makes sense (and why it is unnecessary).

I’m finally confident and looking forward to start printing the parts for a robotic system for my master thesis, so thank you.

One question, what is your opinion on magnetic build plates, especially when printing flat on the build plate? Do you think it is beneficial, or unnecessary with the lower burn-in layer times, etc? Furthermore, to avoid high stresses in the machine (and maybe prevent the stepper motor from skipping steps) when the machine calibrates Z at the beginning of the print, do you think it’s worthwhile to introduce a Z offset in Z=0, before leveling the build plate using the dummy print method? That way you could ensure the build plate does not ‘crash’ into the screen or resin at full speed when it’s calibrating.

Thanks!

I am also very interested to hear Jan’s thoughts on magnetic build plates. I have also noticed stepper motor skips when homing.

Sorry mate I thought you were ” Jan mrazek ” 🙄

Hey Jan. Thanks for the post and the detailed settings. I’m following what you have here but unfortunately, I’m still getting the elephant’s foot when printing. I do use an Elegoo Mars 3 though and was wondering if there’s anything I’d need to change since it’s a smaller printer.

Also – after the UVTools adjustments, should I be seeing a loop of grey pixels around the white pixels in the first few slices? Like a grey stroke so to speak.

Thanks!

There could be also problem with your build platform calibration. Forget about 1 paper calibration from the manual. Try to follow Jan’s method here: https://blog.honzamrazek.cz/2022/06/short-prints-and-squished-layers-on-chitu-powered-resin-printers-solution/ I would just recommend to not touch the build plate at all during calibration, the built in spring is strong enough, just screw the bolts.

I have Mars 3 Pro and my elephant foot is completely gone now. I’m still experimenting with UV tools settings and retraction speed but instead of Jan recomendation I’m using just fixed rest time of about 35 seconds for first 1,5 mm. I’m now in the process of testing different numbers and finding what works still fine. It will also very depend on viscosity of your resin.

Hi

I followed your previous setup and this one but pls would it be possible to get the actual settings you’re using in chitubox for this UV tools tutorial to make sens to me .

Thank you for your help

I hope I can also help. Prepare your model in Chitubox as you usually do, just set your Bottom layer count to 3 and Bottom exposure time to 3x-4x your normal exposure. Then open this sliced file in UV tools and follow the guide above. Last step is just to save your new edited file in UV tools and you can print it.

Thank you for the reply

But the thing is I have the chitubox recommended settings for Saturn and I don’t think they that good .

Layer height 0.050

Bottom layer count 5

Exposure time 2.5

Bottom exposure time 30

Transition layer count 10

Transition type linear

Transition time decrement 2.5

waiting mode during printing resting

Rest time before lift 0

Rest time after lift 0

Rest time after retract 0.500

Bottom lift distance 7 + 0.0mm

Lifting distance 7 + 0.0mm

Bottom retract distance 7 + 0.0mm

Retract distance 7 + 0.0mm

Bottom lift speed 70 + 0.0mm

Lifting speed 70 + 0.0mm

Bottom retract speed 210 & 0.0

Retract speed 210 & 0.0

Another thing is I get nasty horizontal thick lines on printed objects . Thank you your help is greatly appreciated.

Hello!

Firstly, thank you for all the work and contribution to this hobby. Just reading your material makes my brain feel like it’s expanding haha. The intricacies of this hobby and the quality of your experimentation are quite impressive, to say the least.

On to my question, I want to print this:

https://www.printables.com/model/130765-new-planetary-gear-fitget-v20

But find that I wasn’t able to print directly on the bed due to elephant foot fusing the gears together on the bottom layers. So now that I have read your material on how to deal with this, do you believe this print should be possible with modified light off settings and proper delay timings?

Thank you again for all your work!

Worth noting I am using a Saturn 2. 2 second normal exposures, 25 second (very likely too high) bottom exposures for 10 layers.

I haven’t examined the model. If the spacing is more than 0.15mm, I think you should be able to print it just fine. You also have to pay attention to properly cleaning the model. Getting resin of very narrow spaces is quite challenging.

Hello! Thank you for your reply, knowing that there is a potential spacing issue with things being tighter than 150um helped a lot! After sizing the model up to 115%, along with all your tips on rest times (especially with the Saturn 2 and its enormous build plate and resistive forces) I was able to get a great print! After adding g a dab of WD40 the gears sang like a choir of angels!

https://drive.google.com/file/d/1cEPmmq2-9BHF7-eWzivBA4nl4Rag4hst/view?usp=drivesdk

Here’s a picture of how it turned out! Only a 1:15 print! Thanks for all your help and your dedication to this craft!

Hey Jan, thank you thank you thank you for this post and this series, you cleared up a lot of issues I had printing on the build plate and getting prints to stick. Plus, this also cleared up my elephant foot problem before it even started. I am having a new problem now, and that is getting my prints off the bed. I’ve been gouging and scratching my models trying to get them off and wondered if you had any suggestions? Thank you again!!

Thank you a lot for your job!!! UV Tools is excellent and useful. I just start with SLA print and i was afraid, your software is only for Windows. How I made a big mistake. From github Cmd+C to the terminal Cmd+V and all is done… 🙂 Really good job!