I wrote several posts on the precision of the Z-axis and gaining the precision in the XY direction on Elegoo Mars. However, last week I wanted to print models that feature narrow rectangular holes – roughly 0.2 x 0.3 mm. I thought it will be trivial – I have well explored the problem of exposure bleeding and wrote a tool for its compensation.

However, my first experiments were a complete failure. I used Elegoo standard grey and Siarya Fast grey – both without acceptable results. See the photo below (left first results, right expected results). Practically all the holes were rounded and closed in the bottom. No matter how big compensation I used, I got the same result. And when you think about it, it makes sense – the exposure bleeding rounds the sharp corners. If I compensate for it, I might get the correct dimensions of the holes, but I cannot get sharp corners.

The results on the unmodified Elegoo Mars

The results after modyfing the printer

I thought – the holes are only 5 pixels wide, maybe I am running at the edge of what the printer is capable of. Then I took of the resin vat and looked at the pattern the display is showing. It showed a nice, sharp, crisp image of what I wanted to print. Therefore, the limitation is not in the display itself. I took one of my old broken displays from the printer and start to examine it.

There is protective glass on the display (see photo below). The glass is not glued to the display, in fact, it is similar to a glass you can put on your smartphone. It is not held by an adhesive, rather it is some kind of electro-static bond (I actually don’t know the physics behind sticking the protective glass on your smartphone). So it is easy to remove. I thought this glass contains the top polarizer, but it is not the case. This glass is 0.7 mm thick and provides a gap between the resin and the displayed patter itself. This gap provides a space for the beam of light to spread and therefore, to reduce the effective resolution of the display – well – it is one of the significant causes of exposure bleeding.

The Modification of the Printer

So I decided to try an experiment – remove the protective glass and print without it. The good news is there is a piece of glass underneath the display which provides mechanical support for the display (the glass is there to probably protect the top polarizer from scratches and also from resin leaks not to strengthen the display).

To print directly on the display there is a need to lift it by the thickness of the glass. I actually decided to lift the display 0.2-0.3 mm above the vat bottom to ensure my FEP film lies directly on the display – the FEP film stretches over the display. To do so, I printed some spacer I put between the pink base plate and the supportive glass.

The spacers (divided in fourths as the whole frame is bigger than the print area)

Base glass with the spacers

Since I removed the protective glass with a black outside frame, some of the UV-light was passing around the display. I solved it by putting a thin aluminum tape around the display.

UV-light leaking around the dsiplay

The aluminium tape to prevent the leakage

And then the modification was done. Below you can see the vat sitting on top of the display:

Results

I poured resin in and started printing. As you could see in the introduction, the modification helped a lot. See microscope photos below (I am sorry for the poor quality, but I haven’t created a photo shooting jig for an optical microscope). On the left the original one, on the right after modification. One thing you note immediately – you can clearly see individual pixels/voxels after modification. When you look by eye, the prints are matte, not glossy – this is probably due to the “pixelated” surface. In the prints, I used only one bottom layer. You can see that the other layers are nice and sharp, however, the first layer (despite I used only 15 seconds for exposure) is bloated. This is probably caused by the light bouncing off the build plate. But this is only a speculation and I would appreciate the opinion of the others.

Before...

...and after

I also printed the AmeraLab test piece. The result is wonderful. You can see that even the smallest strands on top the building got printed (however they got bent during washing).

Test piece

Test piece

Test piece

Conclusion

I am pleased with the results of this modification. However note that this modification has its downsides – if your resin leaks, you can probably say bye to your display. You can scrape the resing with a razor from the protective glass, however, I think you cannot do the same with the polarizer – the resin will stick to it much better and the polarizer is soft, compared to the glass, so no razor.

Also, this mod adds accuracy, however, it removes nice smooth, glossy surface finish many Mars users are used to. So you get detail for I am not sure if worse, but definitely different surface finish.

I haven’t done tests that measure the amount of the exposure leaking but I expect much fewer problems with it, maybe it will be reduced under a measurable amount. I am also left with an open question on how to deal with the exposure bleeding of the initial layer which is significant even in case I use the same exposure as for regular layers. It would be interesting to put an extremely dark coating on the build plate. However, even if I got vantablack or similar, I don’t know how to protect the paint from the prints and during scraping the prints.

Did you enjoyed the post? Consider supporting me on Kofi:

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

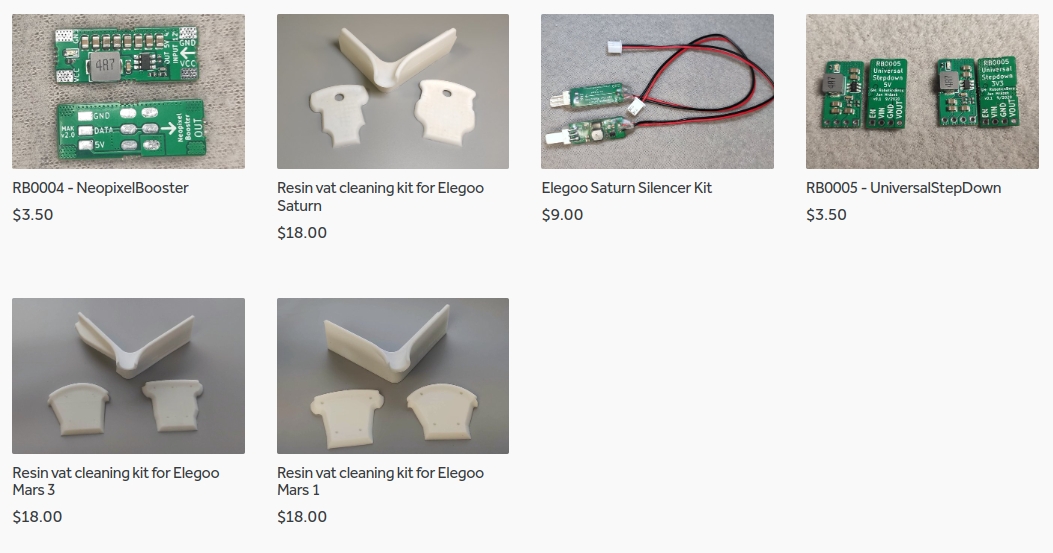

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

The glass is there to help protect the screen from UV damage. You may have just decreased the lifetime of your screen significantly. They are cheap to replace though.

I may have misread the post. I thought you removed the glass underneath the screen. If it was the one on top, then my previous reply does not make sense.

I am removing the top glass (should be clear from the pictures). However, I don’t think the bottom glass is there to protect from UV – the LEDs have a quite narrow emission range and if the glass would filter UV, what would cure the resin then?

Very awesome to hear about this. I too have been thinking about issues with the light bleed due to trying to make small holes, and this helps confirm some of my suspicions.

One thing you could try on your end for more improvement is using either black resin, or adding some black to your grey. The darker pigment means less light bleed. You do have to tweak settings a fair bit to get it working, and black can be so dark it actually requires very long exposures negating the benefits. Definitely lower layer height to help a lot there. For my own dark grey blend, I mix white and black in equal amounts. This has helped things a fair bit.

Vantablack definitely would not work on the build plate. It, and others like it, are immensely touch sensitive. They are essentially a forest of carbon nano tubes ( VANTA even stands for Vertically Aligned Nano Tube Arrays )..so the slightest touch of anything at all flattens those nano tubes and it stops absorbing so much light. In addition, it requires very a very special method to apply.

Black 2.0/3.0 could be worth testing though. These are fairly traditional acrylic paints, they’ve just worked to cram as much of the pigment in as possible.

I must say though, it’s extremely tempting to test out your method. Removing the glass is extremely risky, but it’s not that expensive of a replacement, and those results are spectacular.

Thank you for the suggestion. I tried it: https://blog.honzamrazek.cz/2020/01/does-dark-build-plate-on-an-sla-printer-reduce-exposure-bleeding/

Great idea! Might give this a try as well.

Another aspect of the Elegoo which might adds to the exposre bleeding is the UV light source. All light is coming from the 4 leds in the center and is spread out over the print surface. Even if all light rays would come in a direct line from the leds they hit the LCD and also the resin at an angle (mainly in the outer areas of the build area) instead from straight below. The mirrors around the leds bounce the light rays even more in almost any angle and direction.

I wonder if exposre bleeding problems could be reduced replacing the org leds with an array of UV leds which has the size of the building area. This would allow to mount the leds much closer to the LCD and would probably reduce the amount of light which comes in at random angles instead of from straight below.

I think so and it is something I am currently working on.

Very interesting! Im also interested in MSLA for engineering applications, moldmaking etc, but its clear these machines are not optimized for the purpose. In reviews you see a lot of differences in the smoothness/blockiness of prints, and I suppose this glass thickness is one of the biggest factors then.

I think this also ties in strongly with the effect you get from AA; people report quite variable impressions of it. I imagine if you have massive bleed through, it does almost nothing; and if you dont have any bleed through, it wont do much at all either. Id guestimate you want an effective spot size about twice the pixel size to get best results from AA; having a setup where this is a tunable parameter sure would be neat. Ive heard of this printer with a liquid interface for easy peeling; that might be awesome for dialing in the bleedthrough as well.

Cant find what I was looking for but dont think it was that CLIP stuff thats been around for a while. It involved a non-miscible heavier-than-resin transparant liquid layer.

Annoyed I still cant find it. One could imagine a system involving a thin layer of alkane wax; melting point sits around the printing temp, and with a little cyclic heating you could induce a phase transformation in such a think layer quite rapidly I think. Seems like alkenes generally dont mix with SLA resins much at all. Better yet would be a transparant liquid that you could pull into a very flat and uniform sheet using electrowetting; saturated water-cacl is very dense and great at expelling any organic molecules. Not sure if the thing I seem to remember was like either of these; …. and I would be surprised if this turns out to be an easy elegoo mars mod… just thinking out loud. Might give very nice control over bleedthrough, while getting rid of peeling forces at the same time.

Thank you for the interesting comment. I am not a chemist; what exactly is a water-cacl? I tried to google it, but without luck. Also, could you give an example of alkane wax?

I think he means water + Calcium Chloride (Ca+Cl)

Hey there, I was going to give this mod a shot since I had a screen with a cracked protector. Too bad I accidentally tore the flat cable.

I did want to ask though, does the different surface finish affect paint at all? Or is it something you only notice on bare resin? I’m using my printer mostly for miniatures. Thanks!