In this regularly updated post, I sum up the results of torturing various resins for SLA 3D printing. I have a very fine and functional mechanical model – a 1:85 compound planetary gearbox. The gearbox uses M0.5 teeth (half the LEGO gears teeth size). It is intended to be used with a brushless motor. The overall diameter of the gearbox is 38 mm. Here’s what it looks like:

All printed components of the gearbox

The heard - sun with three planets in a cage.

Completed gearbox

See how the planets are actually small!

The model requires quite tight tolerances (the gears meshing, press-fitting of the bearings), a lot of small details (the teeth of the gear), and shows real-world loading scenarios. So I consider it as a proper torturing piece for practical applications.

In my experiments that should show how a resin is suitable for mechanical functional parts, I print the gearbox 2-3× and measure how much torque it can output before breaking. I also note how nicely it fits, how well the gears mesh, etc. It is not the perfect test (it would be nice to properly test specimens for tensile strength, impact resistance – but I don’t have machines for that), but it gives you a pretty good idea of what to expect from the resins.

The setup for measuring the output torque

The setup for measuring the output torque

Experimental Results

3D-printed Compound Planetary Gearbox

Recent news: My open letter to the 3D-printing community

I love the 3D-printing community, but I think there is room for improvement. Let's get better in 2023! Read the full letter.

Support my work!

If you like my work (these blog posts, my software and CAD models) and you would like to see more posts on various topics coming, consider supporting me in various ways:

- You can become my sponsor on Github.

- If you prefer, you can also become my Patreon.

- You can buy me a coffee on Ko-fi,

- or you can buy something from my Tindie store (also see below),

- Or you can just share my work!

If you are interested in knowing what I am up to and recent sneak-peaks, consider following me on social media (Twitter, Instagram, Facebook).

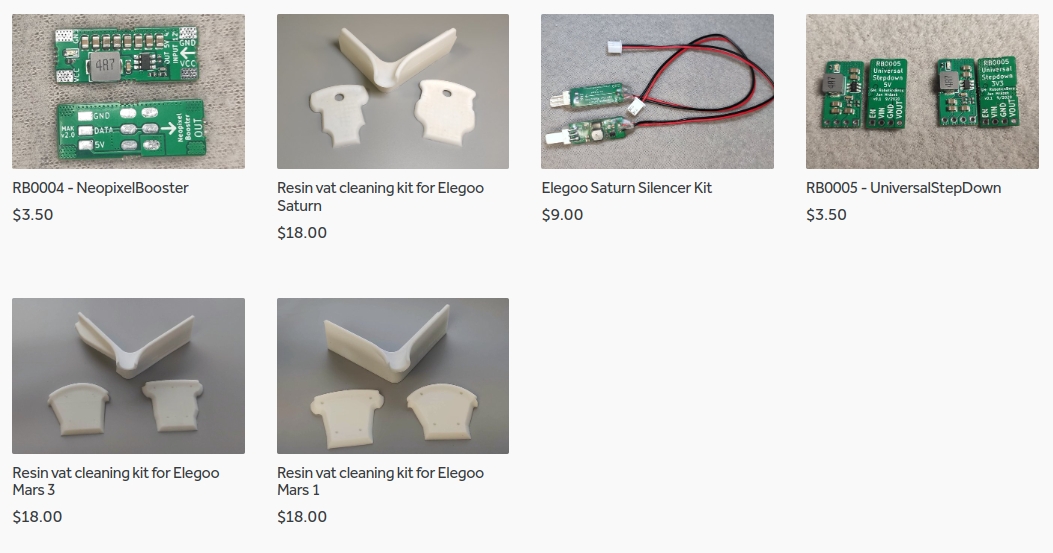

My store offers

I launched new tank cleaning kits for Elegoo Saturn, Saturn S, Mars 1, and Mars 3. You can find them in my store.

Related Posts

- Multi-planar Slicing for 3D Printers – For Both FDM and Resin

- Open letter to the 3D printing community: Let’s be better in 2023! What should we do?

- Continuous Printing On LCD Resin Printer: No More Wasted Time On Peeling? Is it possible?

- About the Successful Quest For Perfect MSLA Printer UV Backlight

2 thoughts on “Overview of Practical Resin Properties”