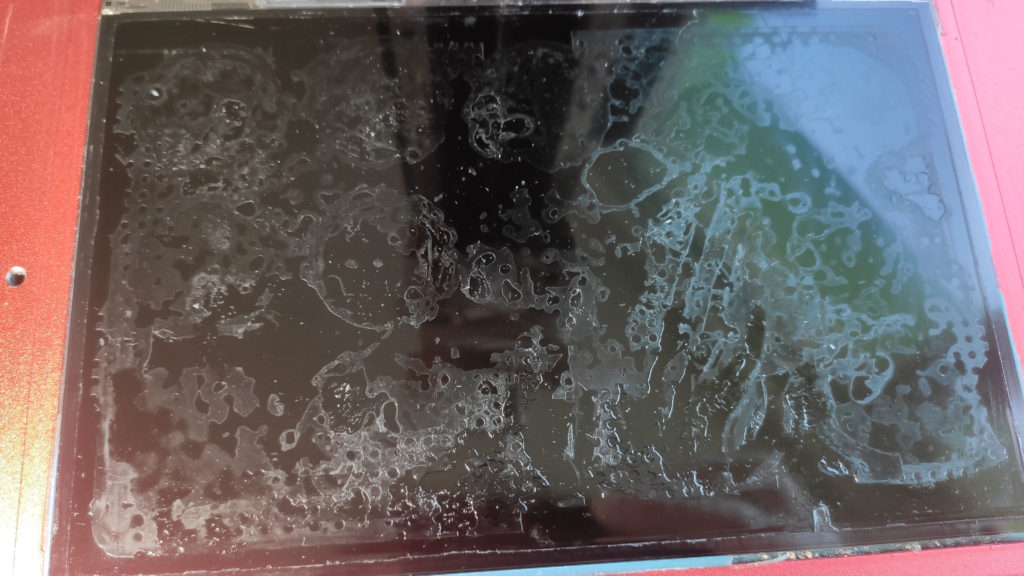

Most polymers shrink when they cure or solidify. That means that their volume shrinks down during the process. The simple consequence is that the models you print either on FDM or resin printer are smaller than you designed. Therefore, when you try to print, e.g., an enclosure for PCB or a hole for a pin or a screw, they might not fit.

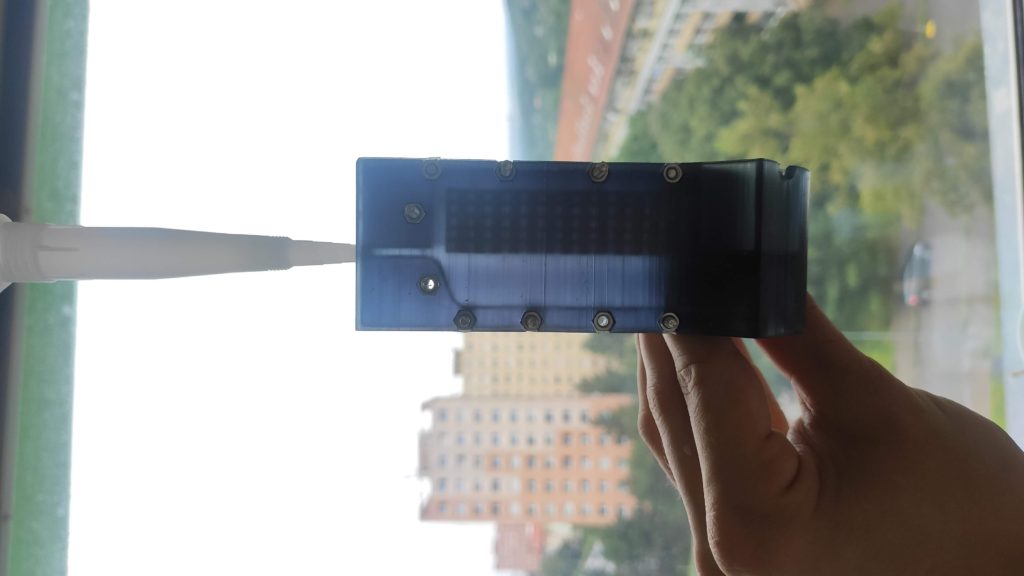

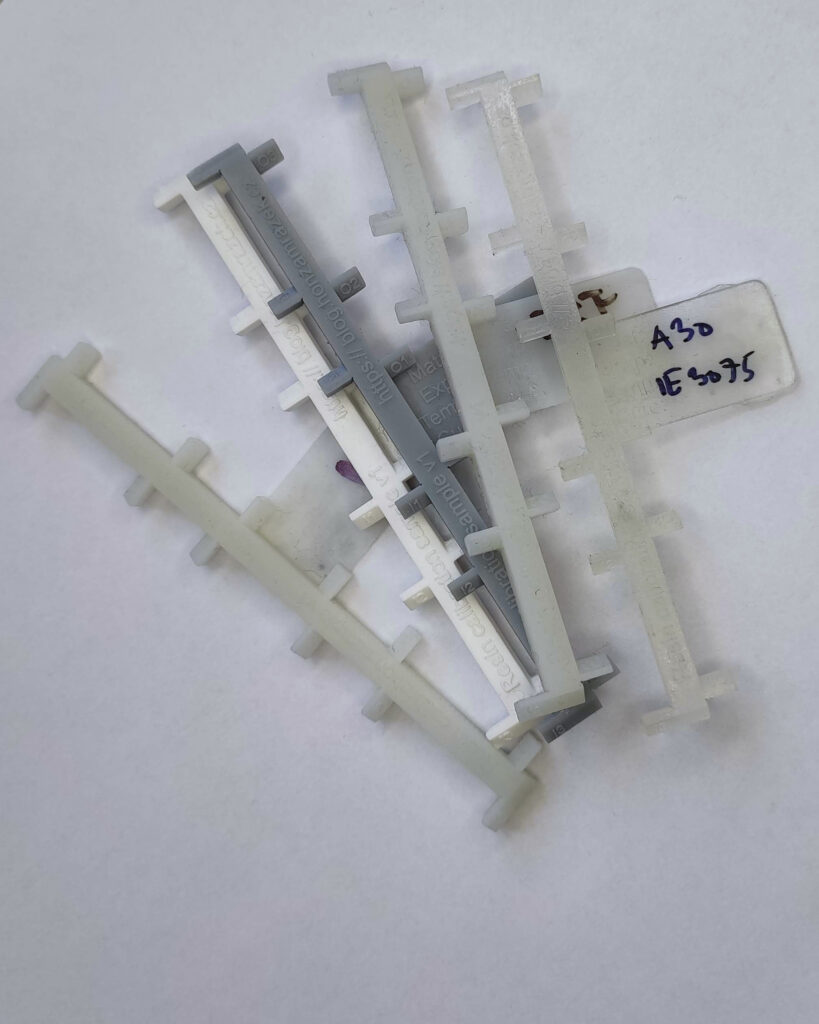

Today, we will explore how serious the shrinkage is, whether it is the only source of dimensional inaccuracy and how to measure it and compensate. After reading this post, you should be able to calibrate your resin printing process such that the models you print will come out perfectly within the accuracy of a single LCD pixel. That is usually roughly 50 µm + the inaccuracies in your measurement setup. We will also show you that you can easily use this test to precisely tell if you overexpose your model or not.

However, since we print quite complex geometry layer-by-layer there are some interesting phenomenons that need to be taken into account. They affect how the printed part wraps. They are complex, so we will dedicate a separate blog post on this topic in the future; today we will start with the basics.

Continue reading “Getting Perfectly Crisp and Dimensionally Accurate 3D Prints on a Resin Printer: Fighting Resin Shrinkage and Exposure Bleeding”